Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

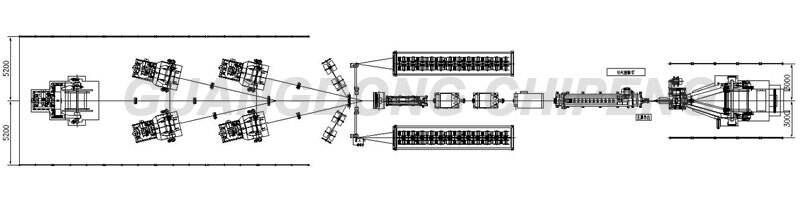

2500/4+1 drum twister machine

The 2500/4+1 Drum Twister Machine is a highly efficient and versatile piece of equipment designed for the manufacturing of large-section and long-length power cables. It is also capable of handling steel wire, steel tape armoring, copper wire, and copper tape shielding processes. This machine is equipped with advanced technologies to ensure precision, reliability, and ease of operation, making it an ideal choice for modern cable production lines.

Key Features

PLC Control: Regulates motor operations, stores parameters, and offers real-time monitoring.

Touch Screen Interface: For setting, displaying, and modifying process parameters.

AC/DC Motors: AC variable frequency motors for pay-off, twisting, wrapping, and traction; DC motor for receiving, ensuring stable performance.

Fault Detection: The PLC system can calculate various operating data and display the type and location of faults on the touch screen, allowing for quick identification and reduced maintenance time.

Cable Pitch Adjustment: Settable and modifiable on the touch screen.

Tension Control: Precise tension control for winding, adjustable on the touch screen.

Safety Measures: Comprehensive protection features, including fault alarms and emergency stops.

Independent Pay-Off Motor: The pay-off rack features a separate motor rotation, making installation, operation, and maintenance easy.

Technical Specifications

|

|

Single wire diameter |

Max pay-off speed |

Max line speed of caterpillar |

Max force capacity of caterpillar |

|

3600 |

Φ25~Φ130mm |

21r/min |

33m/min |

4000kg |

|

3150 |

Φ25~Φ120mm |

33r/min |

50m/min |

4000kg |

|

2600 |

Φ25~Φ100mm |

33r/min |

50m/min |

|

Components

Center Rotating Pay-Off: Fork-type cantilever structure with pneumatic tension control, shaft-less bobbin clamping, and manual control options.

Rotating Pay-Off: Similar to center rotating pay-off, with independent motor drive.

Double-Disc Taping Head: For various materials, with mechanical tension control and automatic parking.

6T Rotating Caterpillar: High-capacity traction with AC variable frequency motor.

Rotating Take-Up: Fork-type support with DC motor, pneumatic brake, and hydraulic bobbin loading.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost